The Momo Homes Story

50 Years of Revolutionizing Industries

A mission to save

the family business

When Gary Gale was 18, his father sent him from Australia to

Germany for technical tertiary education.

All Harry Gale asked was that when his son had completed his

certification, he would return with an idea allowing the family to move

out of the textile business, which was then under a growing threat from

foreign competition.

Somehow, four years later, Gary did.

Perhaps his success was due to his relentless curiosity.

Perhaps it was due to the work ethic he developed during his twice daily two-hour swim training in Melbourne’s Olympic swimming pool.

Perhaps it was because of some audacity inherent in the Australian genome.

But whatever it was, when Gary returned to Australia, he announced to his father, “We’re going into a new industry.”

Within a few years, the Gales had revolutionized a textile industry and positioned the family business at its apex.

A boy with a bit of a wild streak

Early on, however, Harry Gale wasn’t quite sure what to do with his son.

Gary was smart and mechanically minded, but he’d developed, as he put it, “a bit of a wildness.”

At the time, Harry and his wife, Barbara, had their hands full running a textile business. The Gales specialized in the manufacture of children’s clothing, and ran their factory using Raschel knitting technology from Germany.

Since Harry and Barbara spent most of their waking hours at their factory, there wasn’t a lot of time left for raising the kids. Barbara’s mother helped out a bit. And Harry and Barbara also turned to that other time-honored Australian babysitter: the swimming pool.

A routine developed. Harry would drive his kids to morning swimming practice, from 4:30 a.m. to 6:30 a.m. Barbara would take them to the evening session, from 5 to 7.

Before long, there was no real boundary where the Gale family ended and the Malvern Swimming Club began. Gary and his sister, Diane, became club champions. Harry became president of the club. Barbara served as the timekeeping official.

From age 8-18, Gary and Diane swam. Day after day, mile after mile.

“That’s what made us competitive,” Gary says. “Swimming’s a very lonely thing. You’ve got to be very dedicated to stay in it. And we stayed in it.”

The competitiveness, persistence, and discipline Gary learned from swimming lay the foundation for his entrepreneurial career.

It also didn’t hurt that he had a knack for machinery and could fix any machine at his parents’ factory.

No matter how efficiently the Gales ran the factory, however, they still felt the pressure of increased competition from Asia.

Harry could see the writing on the wall.

Something needed to change, and this son of his — creative and disciplined, mechanically minded and a bit wild — might hold the key.

Harry steered his son toward Germany, where a scholarship offer waited.

An idea to reinvent an industry

“He told me to come back with an idea,” Gary says. Something “that’s going to allow us to

get into something unique and more technology driven.”

Gary was 18 at the time.

He’d received a scholarship to Germany’s Karl Mayer school of Raschel knitting, a textile

college that was launching its first English-language degree.

Before long, Gary got an idea for a new kind of plastic textile. To manufacture it, though, he

needed a machine that would continuously knit plastic thread of a type that didn’t exist.

The engineers at Karl Mayer said they couldn’t build it. There were spools that fed the thread

into the machines, and plastic thread is heavy. To get continuous delivery of thread, the

spools would need to be enormous. But the beams that held the spools weren’t designed for

that amount of weight. They’d snap, the engineers said.

Gary persisted. He thought it was possible to redesign machines with new beams would mean the machines would only need to be threaded every 3-4 days.

Impossible, the engineers said.

So Gary went to the beam manufacturers.

The beam manufacturers said they would give it a try, but it would be expensive.

“Doesn’t matter,” said Gary.

With the beams created, Gary told the Raschel engineers to use the beams to make the textile machine he wanted.

It was very large and very expensive. They didn’t think it was practical.

“I’ll have six,” said Gary.

Made in the shade

industry

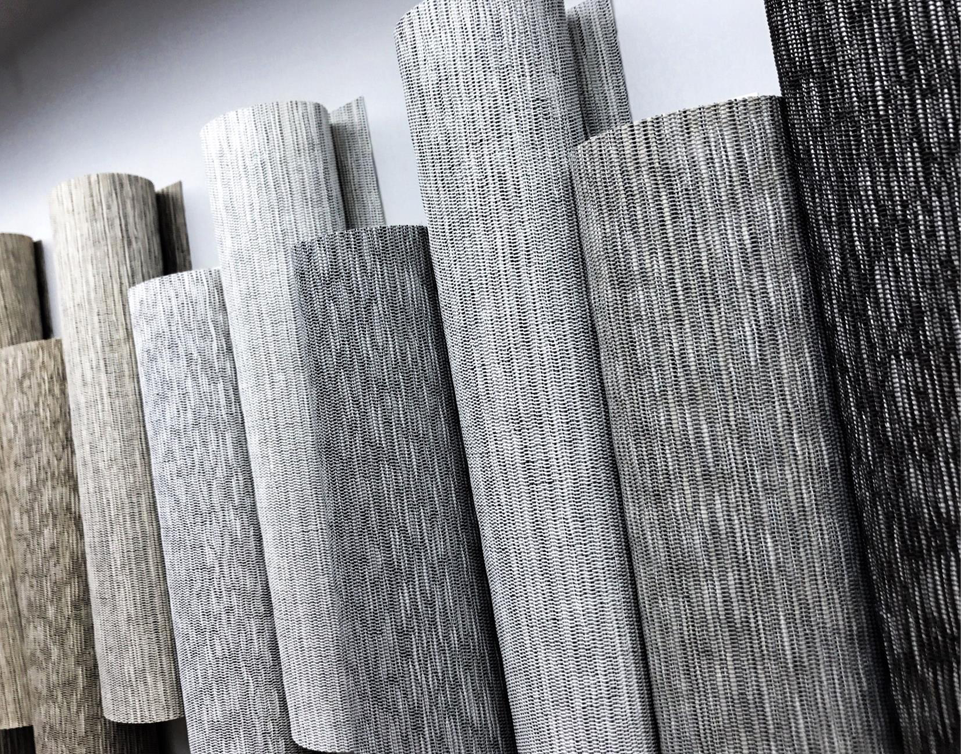

What Gary had in mind was the transformation of the shade fabric industry. Used extensively in farming and gardening, shade fabric is an effective way to increase crop yields in hot, dry climates like that as in much of Australia.

At the time, shade fabric in Australia — indeed, in much of the world — was difficult to work with, expensive to make, and prone to wear and tear.

Gary Gale’s knitted shade fabric overcame all these problems.

Gary set up a company and soon began replacing Australia’s woven shade cloth with the Gales’ knitted fabric. The company established distribution through the largest agricultural distributor in Australia and within a year were the dominant player in the industry.

Harry closed the family children’s-wear business and joined his son in the shade-fabric industry.

Not long after, Gale Pacific, as the company was now called, established a subsidiary in Apopka, Florida. With a U.S. foothold established, they grew via distribution through retailers such as Costco, Price Club, Home Depot, Lowes, and others.

By the mid-90s they were the largest supplier of shade products in both the USA and Australia and had expanded their product line to include gazebos, awnings, and other shade products. Indeed, the company was so successful it was the first company to make the Inc. 500 list six years in a row, and Gary won the Ernst and Young Entrepreneur of the Year award in Florida.

With Gale Pacific the industry leader in shade fabric (a position they still hold), Gary saw an opportunity in another industry.

A revolution in planter-pot

manufacturing

One of Gary’s South African shade-fabric distributors had invented a new way to manufacture plastic pots. The new pots were more durable than existing pots, but only half as thick.

Recognizing an industry-changing innovation when he saw one, Gary partnered with the distributor and soon sold 10 truckloads of the pots to Home Depot.

He was off and running again.

Within a few years, Gary’s company was the largest manufacturer of decorative retail pots in the world.

The biggest revolution of them all — venturing into home manufacturing

Gary lived in China for a number of years, having set up a shade-fabric textile manufacturing operation in Shanghai. While in China, Gary developed a deep knowledge of Chinese manufacturing practices and which he turned toward developing other kinds of industrial products.

One of his clients was the Bunnings chain of home improvement stores (the dominant player in Australia), for whom he began sourcing building materials.

“I got to know the Bunnings senior staff very well,” Gary said, and they asked, “Can you make backyard bungalows?”

“I said ‘Yes we can, because we’re a ‘Yes we can’ company.”

Before long, Gale Pacific and Bunnings together launched Smart Space Homes and delivered around a thousand homes throughout Australia.

After that, single-family homes were a logical next step.

After supplying homes to a Melbourne developer, Gary saw the potential of manufacturing homes in a new way and in a bigger market. So in 2020 he moved to the United States.

While Covid and Chinese tariffs created initial hurdles, they also opened an opportunity. Gary realized that he could take advantage of the quality and efficiency of Asian manufacture if the component assembly took place at a third-party location that a) was located on the supply line and b) had a friendly tariff agreement with the U.S.

Panama was the missing piece. The country is uniquely situated, possesses a skilled workforce, and has a zero-duty agreement with the U.S.

Now, with precision manufacturing established in Asia, pre-assembly factories set up in Panama, an efficient supply chain in place, and an innovative process that includes a proprietary foundation and precision-built components, the groundwork has been done for the biggest revolution of all.

What’s next

The housing industry has been mired in the same inefficient construction techniques for more than a century.

It’s time for a change, and Gary Gale is making big things happen. Just like he’s done since the day he first left Melbourne for Germany.