How to Downsize Your Home: Complete Guide + Moving Tips

Downsizing is simple in theory. Move to a smaller place, take fewer things, enjoy your lighter life.

In practice, it’s more like trying to edit a novel where every sentence is a family memory.

So let’s make it doable.

This guide walks you from “we should probably downsize” to “we are drinking coffee in our new place and I can actually find the mugs.” Along the way, you’ll get a system for decluttering, a moving plan that avoids the classic problems, and a few ways to downsize without leaving the neighborhood (hello, ADU life).

Quick note: local rules, permits, and taxes vary a lot. Use this as a smart starting point, then confirm the details with local pros where needed.

The big idea: downsizing your home isn’t about less, it’s about enough

Most people don’t want “smaller.”

They want easier.

Less maintenance. Lower bills. Fewer stairs. More time. Fewer things to trip over at 2 a.m.

That’s why a bunch of retirement and personal finance advice calls out downsizing as a way to reduce housing costs and home maintenance, but also reminds people it’s not always the right move for everyone.

If you’re weighing the decision, this AARP guide on when to downsize in retirement is a solid reality check.

Translation: downsizing works best when you know what you’re optimizing for.

Step 1: Define your “right size” before you touch a box

This step saves you from regret-packing. Grab a note app, a napkin, or the back of an old utility bill. Write three lists:

1) Your non-negotiables

Examples:

- One-level living

- A second bedroom for guests or grandkids

- A real workspace (not “a laptop on the couch”)

- Walkable neighborhood

- A garage or workshop

- No HOA (or yes HOA, if you like rules and tidy lawns)

2) Your “nice to have” list

This is where things like a soaking tub or a bigger kitchen island can live.

3) Your dealbreakers

Examples:

- Stairs to the bedroom

- A long commute

- No natural light

- Tiny closets that would force you into storage-unit purgatory

Now do one more thing.

The “week-in-the-life” inventory

For the next 7 days, jot down what spaces you actually use.

Not the spaces you feel guilty about.

The spaces you use.

That list becomes your blueprint.

Step 2: Choose your downsizing path

There’s the classic downsizing path, and then there’s the modern “right-size without disappearing” path.

Path A: Move to a smaller home (or rent)

Pros:

- Clean break

- Often simpler logistically

Cons:

- Transaction costs can be spicy (selling costs, closing costs, moving costs)

- You might lose your neighborhood, routines, and favorite grocery store aisle

Path B: Move closer to family (or support)

This is common for caregiving, grandkid proximity, and health reasons.

If this is you, build extra time into your plan for emotions, logistics, and “wait, which items are we keeping for the kids?” conversations.

Path C: Downsize without leaving the neighborhood (ADU strategy)

This is my favorite “why didn’t we consider this earlier?” option.

You can:

- Build an ADU for a parent, grown kid, caregiver, or rental income

- Or move into the ADU yourself and keep the main home (for family, renters, or future flexibility)

This isn’t fringe anymore. Even major mortgage players recognize ADUs as a way to create space for extended family or rental income.

Here’s Fannie Mae’s overview on Accessory Dwelling Units (ADUs) and Freddie Mac’s ADU requirements.

The catch-22: ADU rules are hyper-local. Set expectations accordingly.

Path D: Build a right-sized home instead of hunting for one

Sometimes the market is weird. Sometimes “smaller” is more expensive. Sometimes every listing needs 12 renovations and a spiritual cleansing.

Building can make sense if you want a layout that fits your life now, and later.

(We’ll come back to this in the bonus section.)

Your next chapter deserves a great home.

Smart, stylish, and solar-ready — Momo’s panelized home kits are built for people who want to right-size without compromising. Take a look at what’s possible.

Step 3: Run the numbers (so downsizing actually saves money)

Downsizing can save money. But only if the math works.

Here’s what to consider:

One-time costs

- Home sale costs (agent fees, repairs, staging, etc.)

- Purchase costs (down payment, closing, inspections)

- Moving costs (movers, truck, packing supplies)

- New stuff you didn’t plan to buy (curtains, rugs, a shower rod you swear was “standard”)

Ongoing costs

- Mortgage or rent

- Utilities

- HOA fees

- Maintenance

- Insurance

Tip: If you’re moving to a smaller home but a pricier area, your monthly cost might go up. That’s not “wrong.” It just means your goal might be lifestyle, not savings.

Step 4: Declutter with a system (not a feeling)

“Just start decluttering” is advice in the same category as “just relax.”

Let’s do something more practical.

The 5-bin method (fast, simple, repeatable)

Label five bins or areas:

- Keep

- Sell

- Donate

- Recycle

- Trash

Handle each item once.

If you set it down, it should land in a bin.

If you want a great, practical guide to getting rid of basically anything, Consumer Reports has one.

Start with low-sentiment zones

Do these first:

- Pantry and fridge (check dates, be brave)

- Linen closet

- Duplicates drawer (yes, you own five can openers)

- Garage corner of mystery

Save these sentimental items for later:

- Photos

- Heirlooms

- Letters

- The box labeled “Important” (which is never important)

The “container rule” (aka your new best friend)

Your new home has a certain amount of space.

Your stuff must fit inside it.

Not by force.

By choice.

Pick a container size (one bookshelf, one closet section, one kitchen drawer). Whatever doesn’t fit gets sold, donated, or recycled.

If you’re overwhelmed, outsource part of it

If you want specialized help, look into a Senior or Specialty Move Manager. The National Association of Senior & Specialty Move Managers (NASMM) can help you find someone who focuses on organizing, downsizing, relocating, and aging-in-place transitions.

Step 5: Measure twice, move once

A common downsizing heartbreak:

You keep the beloved couch.

Then it arrives.

Then it becomes the couch that ate your living room.

Do a quick floor plan

You don’t need fancy software.

Try one of these:

- Sketch the new space with basic measurements

- Use painter’s tape to outline furniture footprints

- Measure doorways and hallways (so you don’t discover “it doesn’t turn” at the worst possible moment)

Keep a “big items” list

Measure and record:

- Sofa

- Bed frames

- Dining table

- Dressers

- Desks

If an item won’t fit comfortably, let it go before it costs you money to move it.

Step 6: Build your downsizing timeline (so the move doesn’t eat you alive)

Here’s a timeline you can actually follow.

8 to 6 weeks out

- Pick your move date (or date range)

- Get at least 3 mover quotes

- Start decluttering the low-sentiment zones

- Create a folder for contracts, receipts, and “where did I put that?” documents

5 to 3 weeks out

- Book movers or reserve a truck

- Start packing non-essentials

- Set up donation pickups or drop-offs

- Take photos of valuables (for insurance and sanity)

2 weeks out

- Confirm mover details in writing

- Pack a little every day (future-you will be grateful)

- Start consuming freezer food and pantry food

48 hours out

Pack a “first night” bin:

- Sheets

- Towels

- Toiletries

- Meds

- Chargers

- Basic tools (screwdriver, tape measure)

- Pet supplies

- Coffee kit (this is not optional)

Moving day

- Do a final walkthrough

- Photograph empty rooms

- Keep important documents with you, not on the truck

Step 7: Hiring movers (without getting scammed)

Moving fraud is real. And it tends to spike when people are stressed and on a deadline.

If you’re making an interstate move, start with the official resources:

- FMCSA’s Protect Your Move

- FMCSA’s tool to search for a registered mover

FMCSA notes that interstate movers must be registered and have a U.S. DOT number.

Binding vs non-binding estimates

This matters because it affects what you can be asked to pay at delivery.

| Estimate type | What it means | What to watch for |

|---|---|---|

| Binding | Price is locked (unless you add services) | Make sure everything is listed in writing |

| Non-binding | Final cost can change based on actual weight and services | Be prepared for the bill to be higher than the estimate |

FMCSA explains the “110% rule” for non-binding estimates: at delivery, you generally can’t be required to pay more than 110% of the non-binding estimate to get your shipment, with remaining charges billed later. If you want the exact details, FMCSA lays it out in their estimating charges guidance.

Red flags (trust your gut)

- No in-person walkthrough or detailed inventory, but they give a “great” price anyway

- Huge upfront deposit

- No physical address

- Vague paperwork

- Pressure to sign immediately

The FTC has a helpful checklist on avoiding moving company scams.

Step 8: Packing tips that save time, money, and your back

Packing is a game of tiny decisions and you want to make those decisions easier.

Rules that work

- Heavy items in small boxes

- Light items in big boxes

- Label boxes with room + contents + priority

- Pack screws and hardware in labeled bags and tape them to the furniture

Create a “do not move” zone

Put these in one place:

- Keys

- Wallets

- Passports

- Medications

- Jewelry

- Laptop

Then tell everyone: this pile does not get packed.

If you want a straightforward checklist, this National Association of Realtors consumer guide has solid basics.

Step 9: Change-of-address and life-admin checklist

This is the part that too often goes overlooked but that keeps your life running smoothly.

Mail forwarding (do it the official way)

Start with USPS Change of Address.

Also, scam sites are a thing. The Postal Inspection Service has a guide on change-of-address scams.

IRS address changes

If you need to update your address with the IRS, start with the official page on Form 8822 (Change of Address).

Don’t forget

- Utilities and internet

- Insurance providers

- Banks and credit cards

- Doctors, pharmacies

- Subscriptions

- Schools and childcare

- Voter registration and DMV (rules vary by state)

Step 10: Offload responsibly (without creating a mini landfill)

Downsizing is a great time to stop moving broken stuff from house to house.

(It’s okay. We’ve all done it.)

Electronics

EPA’s guide to electronics donation and recycling is a good starting point.

Household hazardous waste

Paints, cleaners, oils, pesticides, and similar products should be handled carefully. EPA’s overview on household hazardous waste (HHW) explains what to do and how to find local disposal options.

Donate like a pro

If you’re donating, donate the good stuff.

Clean it. Bundle it. Make it easy for the next person.

Step 11: Unpack like a minimalist (even if you’re not one)

You don’t have to become a minimalist. You just need a few minimalist habits.

Unpack in layers

- Essentials first

- Daily-use items next

- Everything else only if it earns its way into your life

The “one box quarantine” trick

Pick one box of borderline items.

Label it “Quarantine.”

If you don’t open it in 60 days, donate it.

Yes, it feels ruthless.

No, you won’t miss 90% of it.

Bonus: Downsizing with an ADU or a right-sized new build

Sometimes downsizing isn’t “move away.”

Sometimes it’s “build the right thing, right here.”

Why people downsize into an ADU

- Stay in your neighborhood

- Keep family close, but not too close (important nuance)

- Create rental income potential

- Reduce stairs, maintenance, and energy use

If you’re exploring this route, Momo’s ADU lineup spans roughly 393 to 1,120 sq ft, from studio layouts to 2-bedroom options. See the full catalog of Momo homes and ADU designs, or peek at a few examples:

The underrated perk: a smaller home can be a better home

When you build new, you can bake in the stuff that makes day-to-day life easier:

- One-level layouts

- Wider doors and simple circulation

- Smart storage (the kind that prevents clutter, not hides it)

- Better insulation and air sealing for comfort

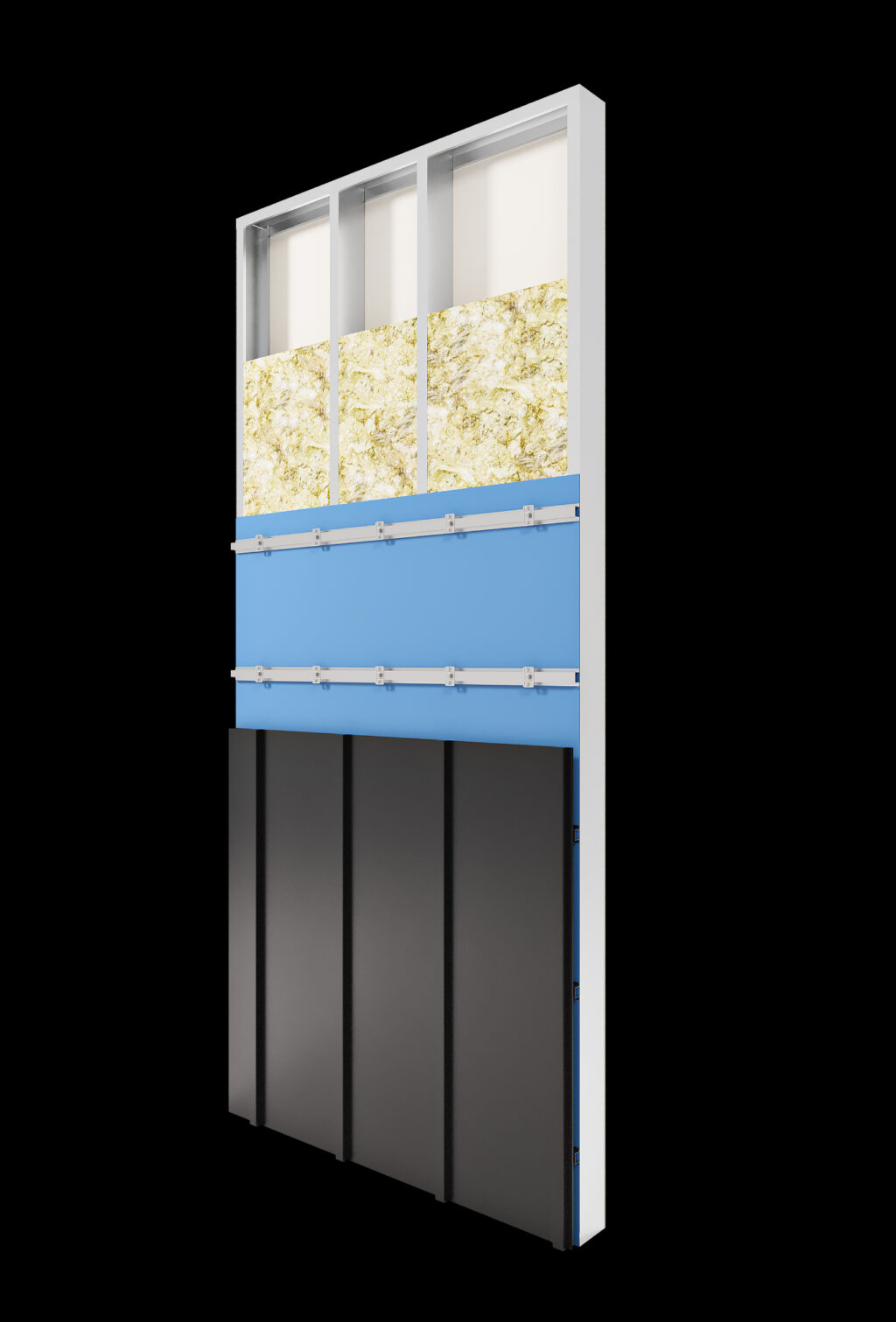

Momo builds panelized home kits and ADUs with a steel structural system and a proprietary foundation approach.

The point is to make high-quality builds more consistent and less wasteful.

If you want to dig into what’s included, our quick reference guide and elements overview are the best jumping-off points.

FAQs

How long does downsizing take?

If you’re starting from scratch and doing it thoughtfully, 6 to 12 weeks is a common range for decluttering + planning. If you’re on a tight timeline, you can do it faster, but you’ll want more help and fewer “maybe” piles.

What if I’m downsizing and I feel weirdly sad about it?

Completely normal since downsizing is change. AARP has a thoughtful piece on coping with downsizing that helps if you’re feeling that emotional whiplash.

How do I reduce fall risk in my new home?

Clutter reduction helps more than people think. For practical room-by-room ideas (grab bars, lighting, removing throw rugs), the National Institute on Aging has a great guide: preventing falls at home.

What’s the single best moving tip?

Get everything in writing. And verify your mover. Start with FMCSA’s registered mover search tool and the FTC’s moving scam guidance.

Final thought

Downsizing is not a one-weekend project. It’s a design decision.

Design your next chapter like you mean it.