An introduction to cold-formed steel (and why you’re gonna love it)

We’re big fans of cold-formed steel. After all, we’ve built our homes—and our business—around it.

Cold-formed steel (CFS) has been the framing material of choice in Australia and New Zealand for decades. And CFS (also called cold-rolled steel) has been a key component of commercial construction for quite a while.

But for residential homes, it’s only recently gotten big notice and devoted fans here in the States.

Why?

Because advancements in features like panelized systems mean that residential home frames can now be manufactured off-site, like in a climate-controlled facility.

And even steel appreciates some air conditioning.

So what is cold-formed steel, exactly?

CFS is the framing material we use for each of our residential homes. Like standard hot-rolled steel, CFS involves rolling the steel at more than 1,700 degrees Fahrenheit. But it doesn’t stop there.

After the heating, the steel is cooled at room temperature and then re-rolled, ensuring both a stronger kind of steel and a more precise finish.

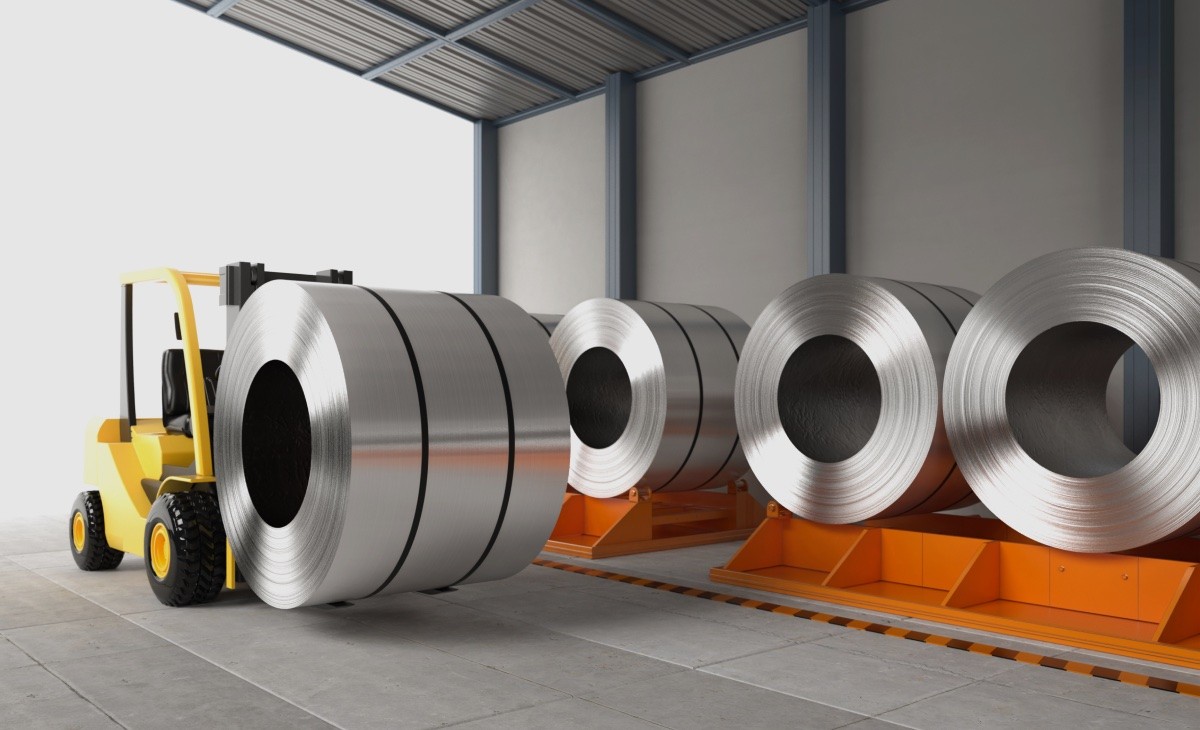

The steel is coiled onto spools of varying widths for shipment, and then fed into a roll-forming machine where it is turned into wall frames, trusses, joists—you know, the important stuff that frames a solid home. CFS frames and components can be formed at high speed and in large quantities with quality and precision.

What are the top five benefits of cold-formed steel?

1. Speed. CFS construction is a design-led process. That means the need for skills to construct a building is higher in the design stage and lower onsite. The construction frame components emerge from the factory precision-crafted and ready for fast assembly. A small team can frame a typical house in 2-3 days.

And let’s face it, when it comes to construction, fast is a word everyone likes. For builders and home owners alike, construction delays are the stuff of sleepless nights. But with CFS frames, builders can commit to tight timeframes and budgets with confidence.

2. Cost. Faster construction means less demand for onsite skilled labor.

3. Pest Resistance. We have yet to meet a steel-munching termite.

4. Durability. CFS won’t absorb moisture, so there are no weather-related construction delays. It also poses very low risk for fire damage, and isn’t prone to warping, shrinking, splitting, twisting or other “-ing” words that provoke migraines in otherwise sane people.

5. Sustainability. CFS is 100% recyclable, won’t lose its quality over time, and meets the highest sustainability standards in all major green building ratings, including the U.S. Green Building Council’s LEED© program. Green is our favorite color, and a value we hold dear.

We could go on. But we’re sure there’s plenty of other tasks on your to-do list. Like building a stylish, secure, and sustainable new home.

For a deeper dive into Momo Homes, feel free to check out our FAQ section, or reach out and let us know how we can help.

We’re pretty sure you’ll become a fan of cold-formed steel, too.

Cheers,

Mike

Mike McAllister is head of story for Momo Homes.

Track the global transition to sustainable homebuilding.

Subscribe to the Momo Focus newsletter.